Welding Butt Joint

w 5 5 w 15 W 4 SLIP FIT FIXTURE W 4 W 4 W 5 W W TOUNGE AND GROOVE VARIATION STEP JOINT VARIATION 45˚ 45˚ Figure 1.The diagrams show time temperature curves for a common butt

4th Floor Nexor Bldg., 1677 Quezon Avenue, West Triangle, Quezon City, Philippines Tel. Nos.: (02) 9275441 / 3868056 / 4104288 * Telefax No.: (02) 4150143 www.nexorpipes.com * [email protected]

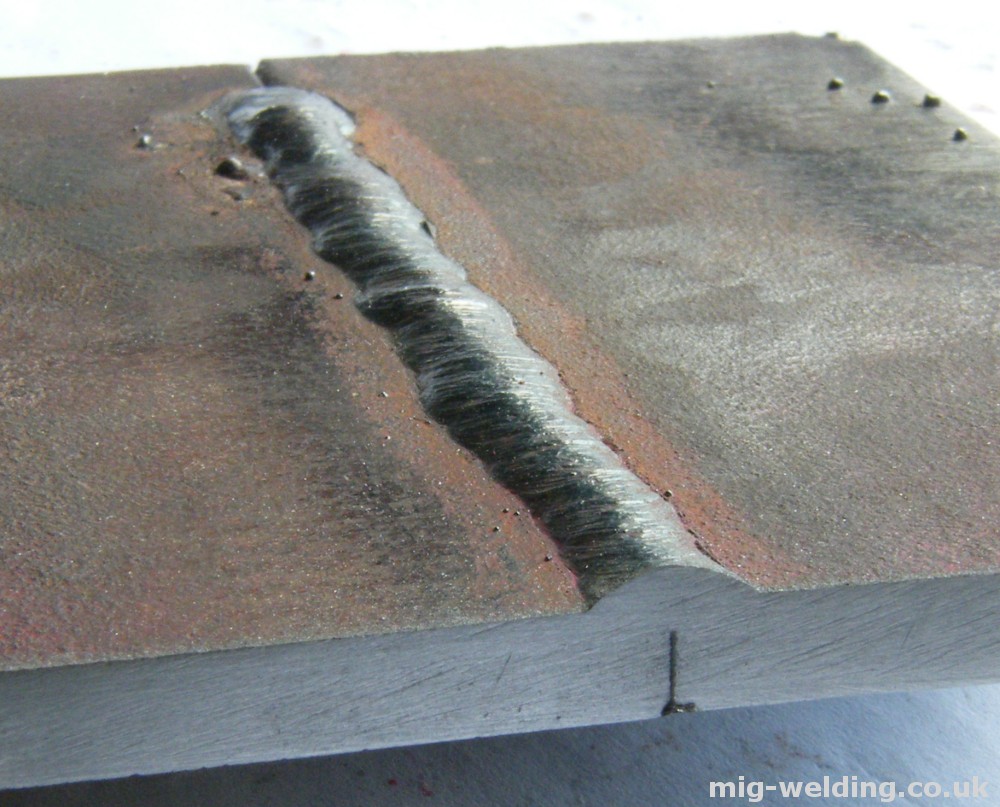

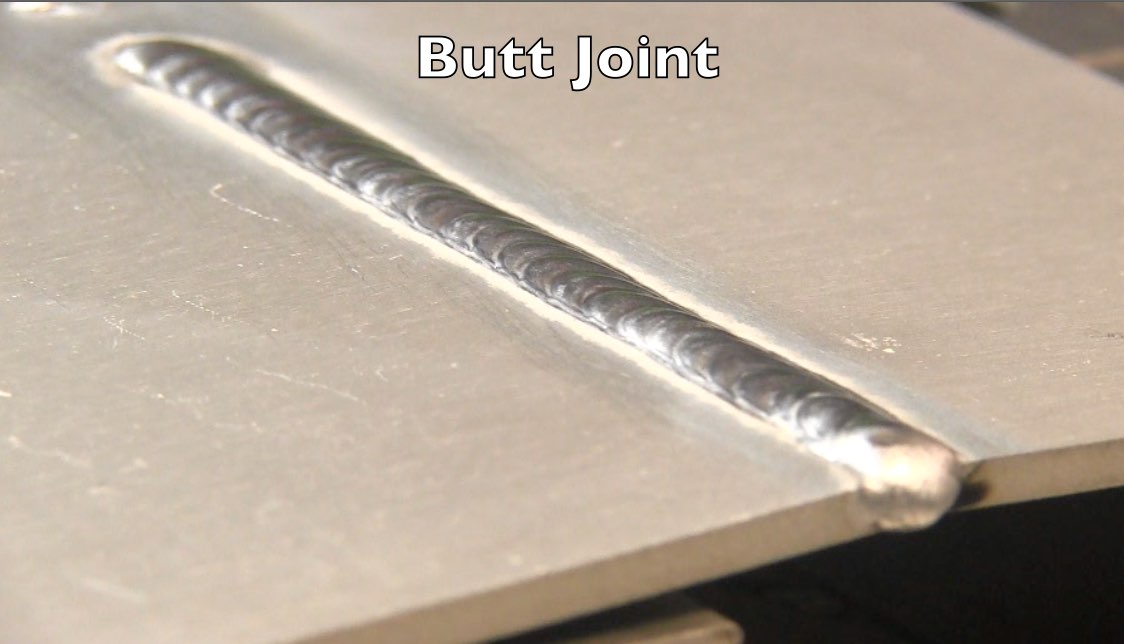

There are many types of butt welds, but all fall within one of these categories: single welded butt joints, double welded butt joint, and open or closed butt joints.

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing fusion, which is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

In the process of selecting a suitable butt weld joint preparation for thick plate (greater than 1 in), the most apparent consideration is unquestionably the joint economy – the practice of minimizing the volume of weld metal required to fill the joint. This desire to keep costs low is certainly

Flange types. As already described before, the most used flange types acc. to ASME B16.5 are: Welding Neck, Slip On, Socket Weld, Lap Joint, Threaded and Blind flange.

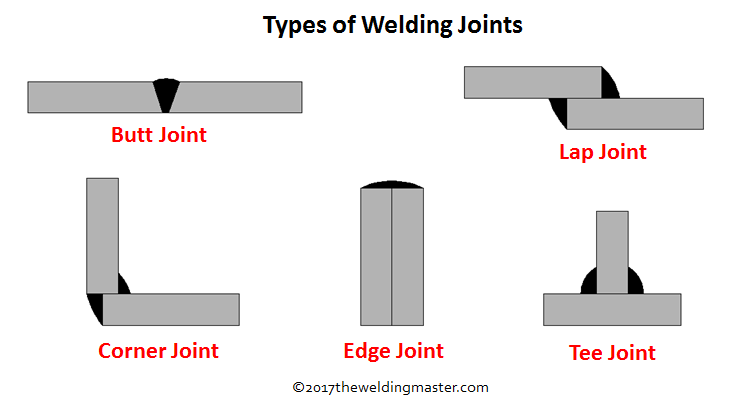

4-1. JOINT TYPES Welds are made at the junction of the various pieces that make up the weldment. The junctions of parts, or joints, are defined as the location where two or more nembers are to be joined.

ROOT OPENING (R): root opening is the little gap between two separate base metal to make root pass (the first pass in welding butt joint where you purposely allow some burn through to fill the other side of the weld joint) possible.

This engineering drawing shows different types of geometry of butt welds. “Welds can be geometrically prepared in many different ways. The five basic types of weld joints are the butt joint, lap joint, corner joint, edge joint, and T-joint (a variant of this last is the cruciform joint).

The main advantages of Flash Butt welding is the speed and the overall strength of the process, there is no foreign weld material used meaning the product can be heat treated afterwards further increasing tensile strength.